Precision-Crafted Foam Solutions for Every Need

At Foamkart, we specialize in high-quality custom foam products designed to meet exact specifications. Whether you need protective foam packaging, precision foam inserts for cases, or specialized EVA/XLPE foam solutions, our advanced fabrication capabilities ensure unmatched accuracy and durability.

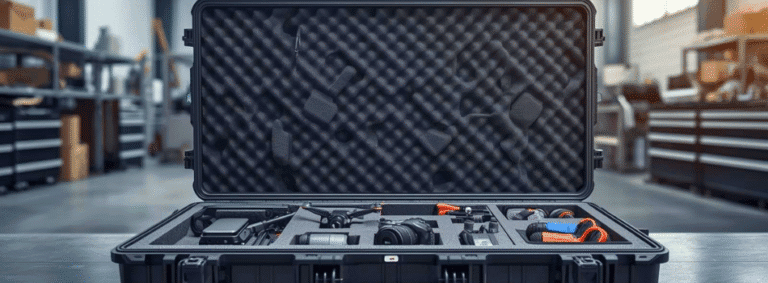

Custom foam packing for Unicase hard plastic gun and rifle cases

Customized foam fabrication for camera and related accessories

Customized foam fabrication for drones and related accessories

Customized foam packing for Handtools

Our Offerings

We specialize in various foam types, including closed-cell and open-cell varieties. We offer custom-made foam fitments and inserts crafted from EPE, XLPE, and PU for diverse applications, tailored precisely to your specifications. Here are some examples of our product offerings.

Looking for Custom Order

FAQs - Custom Foam Packaging & Inserts by Foamkart

What are custom foam products?

Custom foam products are precision-engineered foam solutions designed to protect, organize, and cushion specific products. Foamkart manufactures custom foam inserts, packaging, and padding tailored to exact dimensions, helping businesses reduce transit damage, improve safety, and enhance product presentation.

How do custom foam products benefit businesses?

Custom foam packaging:

- Reduces product damage during shipping

- Improves organization and handling

- Enhances brand presentation

- Lowers replacement and logistics costs

- Provides consistent protection across shipments

What types of foam packaging solutions does Foamkart offer?

Foamkart offers:

- Custom foam packaging inserts

- Protective foam packaging

- EVA foam packaging

- XLPE foam inserts

- Anti-static (ESD) foam packaging

These solutions are widely used for electronics, tools, medical devices, automotive components, and fragile equipment.

What is the difference between custom foam inserts and standard packaging?

Custom foam inserts are precision-cut to match the exact shape of your product, unlike standard packaging. They prevent movement, absorb impact, and offer superior protection, while also giving a clean, professional appearance.

Can Foamkart create foam inserts for hard cases and toolboxes?

Yes. Foamkart specializes in custom foam inserts for hard cases, toolboxes, carrying cases, and industrial storage systems. These inserts improve usability, keep tools organized, and ensure equipment stays securely in place.

Do you provide bulk custom foam fabrication services?

Yes. Foamkart supports small to large-volume production using CNC milling, die cutting, and advanced foam conversion techniques. Our fabrication process ensures accuracy, repeatability, and consistent quality at scale.

What foam materials are available for custom foam packaging?

Foamkart offers a wide range of materials:

- XLPE Foam – Durable, closed-cell, chemical resistant

- EVA Foam – Flexible, resilient, premium finish

- EPE Foam – Lightweight, shock-absorbent

- PU Foam – Soft cushioning

- ESD / Anti-static Foam – Safe for electronic components

Material selection is based on application, load, and protection requirements.

What are the advantages of EVA foam packaging?

EVA foam packaging offers:

- Excellent impact resistance

- High flexibility and durability

- Smooth, premium finish

- Snug-fit protection for high-value products

It is ideal for consumer products, electronics, tools, and presentation cases.

Do you manufacture custom XLPE foam inserts?

Yes. Foamkart manufactures custom XLPE foam inserts known for their strength, closed-cell structure, and resistance to chemicals and moisture. XLPE foam is commonly used in automotive, defense, aerospace, and industrial applications.

Can you convert client-supplied foam into custom shapes?

Yes. Foamkart provides foam conversion services, including cutting, shaping, and fabrication of client-supplied foam sheets using high-precision machinery.

How long does it take to deliver custom foam solutions?

Delivery timelines depend on design complexity and order volume. Most custom foam solutions are completed within a few days to two weeks, with clear updates provided throughout the process.

Latest Blogs